Deploy Once. Adapt Endlessly

Evergreen hardware leveraging the latest in AI imaging for manufacturing.

The Problem

Manufacturing in Australia is under constant pressure, and with insurance companies demanding better safety systems, manufacturers are once again forced to adapt.

You already have existing camera infrastructure available; what if you could use it to both improve safety and alleviate insurer pressure AND extract operational enhancements?

This is precisely what we are providing at SAPHI with our latest innovation, an evergreen hardware solution called 'Shellshock AI'.

Read on to find out more.

What is Evergreen Hardware?

A system designed to be enduringly relevant, able to alter its value with a simple software change. It's built to grow and scale with an organisation, accommodating new functionalities over time without needing physical upgrades.

Introducing Shellshock AI

Safer & More Efficient Operations

One system, two streams of value.

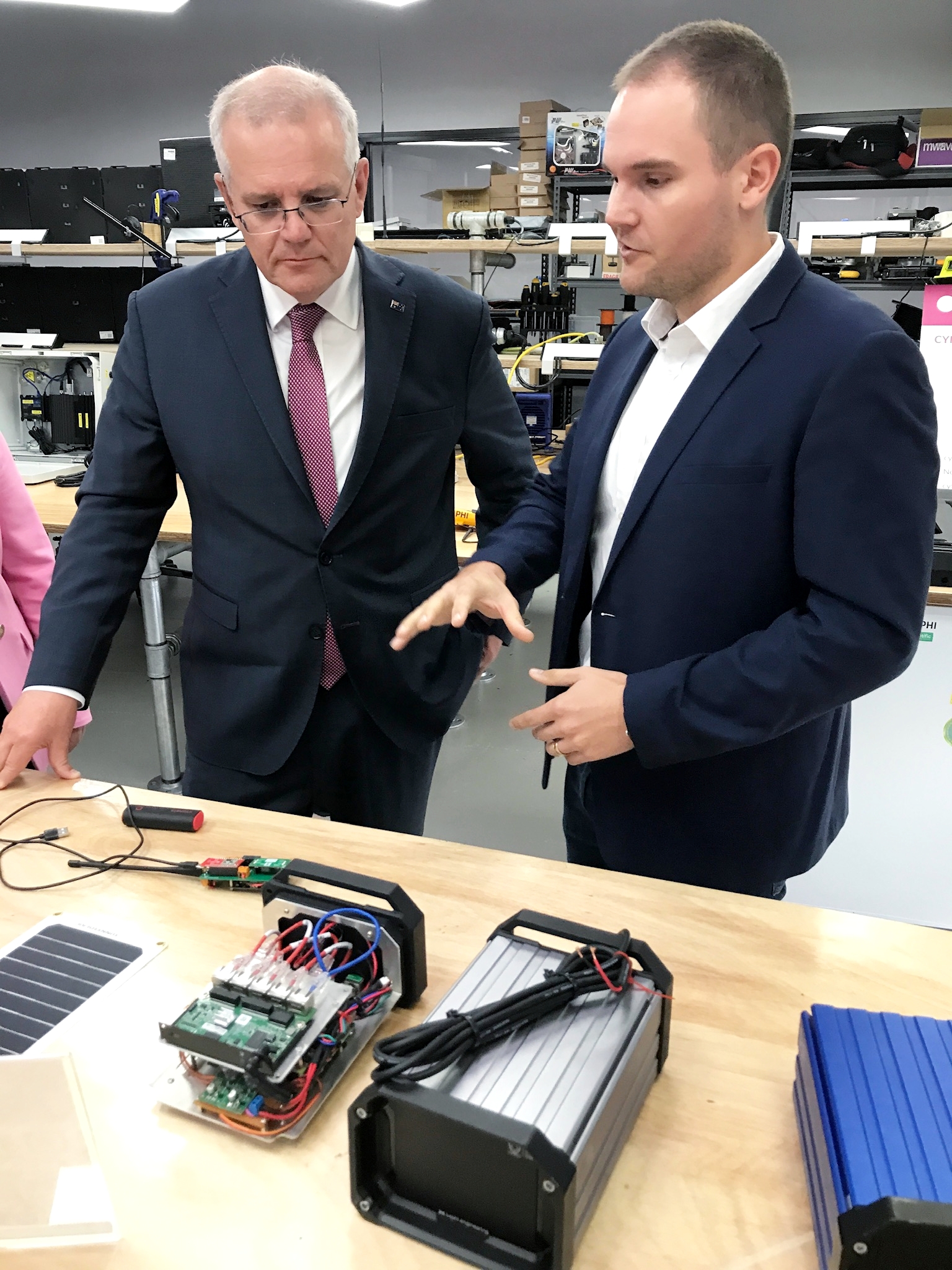

Shellshock AI is a highly sophisticated, Australian-designed and developed AI solution for enhancing safety and efficiency in the manufacturing industry.

Tailored to integrate into your existing visualisation platforms and systems, Shellshock AI delivers advanced algorithms tailored to your organisation to keep employees safe while providing hard data on workplace efficiency.

Unlike traditional data collection tools, Shellshock AI doesn't just capture data, it makes sense of it so you can take immediate action where it is needed most.

- Failed Part Analysis

- PPE Compliance Monitoring

- Vehicle Movements Tracking

- Workshop Utilisation

- Custom Models

What We Are Solving

Using one solution to enhance both productivity and safety in REAL-TIME.

Click the '+' icon to expand

In any manufacturing environment, safety is paramount—not just for compliance but to protect the well-being of every employee. ShellShock AI enhances safety protocols by monitoring for potentially dangerous behaviours and ensuring compliance with safety regulations.

Our AI systems actively scan for distracted vehicle operators, check PPE compliance, and maintain proximity awareness to prevent accidents before they happen. By continuously monitoring these aspects, Shellshock AI helps reduce the risk of critical incidents and builds a safer workplace for everyone.

Shellshock AI enhances quality control in manufacturing by leveraging advanced AI to perform precise and continuous inspections. This system automatically detects defects and deviations in real-time, allowing for immediate corrective actions.

By ensuring consistent product quality and reducing the rate of errors, Shellshock AI helps maintain high standards while minimizing waste and rework.

This proactive approach to quality control not only safeguards product integrity but also supports compliance with industry regulations and customer satisfaction.

Shellshock AI optimizes workforce efficiency by allowing high-value staff to focus on specialized tasks. Our AI technology handles routine duties, enabling skilled workers to concentrate on complex, hands-on activities that maximize their expertise.

This not only boosts productivity and job satisfaction but also aids in the training and upskilling of newer employees, ensuring that expert workers are utilized where they are most needed. This strategic focus helps maintain a highly skilled, efficient, and satisfied workforce.

One critical challenge in the manufacturing sector is losing irreplaceable domain knowledge when experienced workers retire or leave. Shellshock AI addresses this issue by codifying the expertise of these seasoned professionals into sophisticated algorithms.

This technology allows even less experienced personnel, such as a trades assistant, to perform complex failure analysis of parts with the proficiency of someone boasting 25-30 years of experience.

By embedding this knowledge within your organization, Shellshock AI ensures that your most valuable skills and insights remain integral to your operations. This frees up your veteran staff to focus on hands-on tasks where their expertise is most needed.

Understanding and optimizing how time is spent in the workshop is vital for improving productivity and efficiency. Shellshock AI employs advanced algorithms to monitor and analyze the time allocation across different activities—such as checking off parts, computer usage, and hands-on work.

This system provides a comprehensive aggregate view of workshop productivity without capturing or storing personally identifiable information. Instead, it focuses on the overall distribution of time, helping managers identify areas for improvement and better allocate resources.

Why Shellshock AI?

Shellshock AI is a dynamic system designed to capture the data most critical to your manufacturing operations.

SAPHI's Shellshock AI system is designed with adaptability at its core. Today, it might monitor PPE compliance and distracted forklift operators; tomorrow, it could be gauging failed parts analysis or all of them simultaneously. This dynamic system adjusts remotely based on what you need to see and know.

Think of it as insights without limits: if your eyes can spot it, Shellshock AI can measure & report it. Versatile, responsive, and tailored to your shifting needs.

With Shellshock's ability to integrate directly into existing systems and infrastructure, operations can continue on as usual and with a click of a button, insights will begin to surface.

Security sits at the heart of our design philosophy. At SAPHI, we've engineered Shellshock to process data using edge computing with the strictest possible security architecture.

Traditional technical assets decrease in value the longer they run, often requiring increasingly frequent replacements.

With AI imaging, the longer the systems run, the better they get and the more value they deliver. As cameras are replaced, the intelligence of the models remains, providing timeless value.

We recognise that another dashboard isn't what you're looking for, and we're not here to add to that clutter. Instead, with our tailored integration add-on, we'll channel the data directly into the platforms you're already familiar with and prefer. It's about making things seamless and efficient for you.

The Unparalleled Advantage

The essence of our evergreen solution lies in its exceptional deployment philosophy:

Install once, adapt endlessly.

With Evergreen Hardware solutions, the initial deployment lays a robust foundation upon which the functionality can be modified or expanded according to emerging needs or goals without additional hardware changes. This adaptability ensures that your system not only meets current demands but is also poised to address future challenges, making your initial investment perpetually valuable and aligned with your operational trajectory.

- Future-Proof Technology: Eliminates the need for frequent hardware upgrades, ensuring your system remains at the forefront of technological advancements.

- Adaptable to Emerging Needs: Seamlessly integrates new functionalities or AI models to respond to changing operational requirements or safety standards.

- Scalability: Easily scales with your operation, whether expanding in scope or adapting to new challenges, without significant additional investments.

- Continuous Improvement: Regular updates and enhancements keep the system optimized for peak performance and advanced capabilities.

- Enhanced Operational Insight: As new models are developed to interpret evolving datasets, your operational insights deepen, supporting more informed decision-making.

- NO Downtime: Updates and model deployments are conducted remotely, ensuring minimal interruption to your operations.

- Increases in Value: The longer the systems run, the more valuable they become to the organisations. As cameras are replaced, the intelligent models remain.

- Customisation: Tailors monitoring and analysis to your specific operational context, enhancing relevance and effectiveness.

By choosing our Evergreen solution, you're not just investing in a monitoring system; you're securing a dynamic partner capable of evolving with your business, ensuring that your operational safety and efficiency are always supported by the latest in intelligent monitoring technology.

High-Level Specs

Below is the high-level specs for the implementation of the SAPHI Shellshock AI solution.

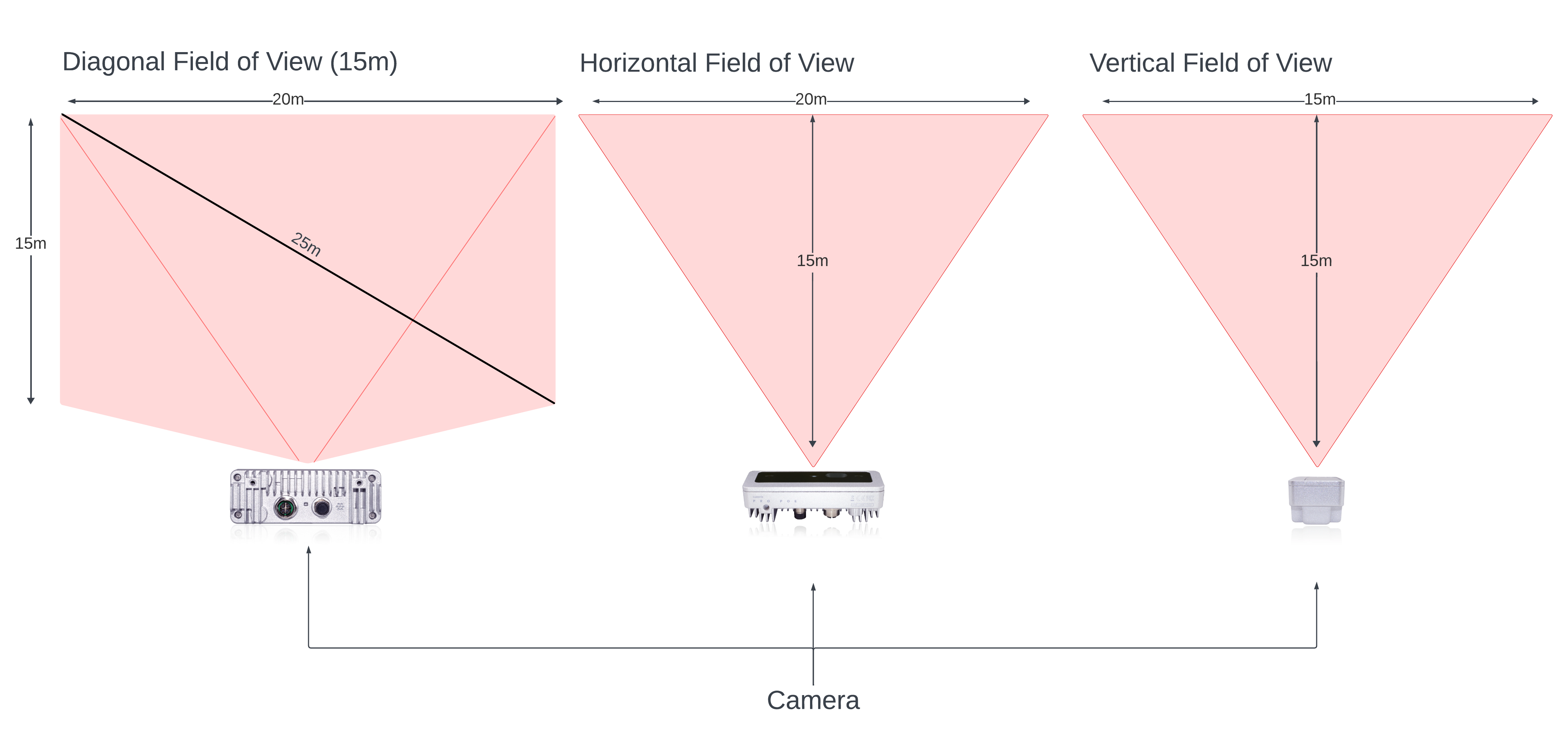

General field of view

While our models can be adjusted to cater to varying distances, the foundational field of view inherent to the Shellshock AI system is depicted in the accompanying diagram.

Both the solar-integrated and premium versions include a triangular pole mounting bracket for streamlined installation.

Power

Our camera system is efficiently engineered to operate on 12-24V power, consuming only 12W per unit. This design allows for seamless integration with both mains power and sustainable solar energy solutions.

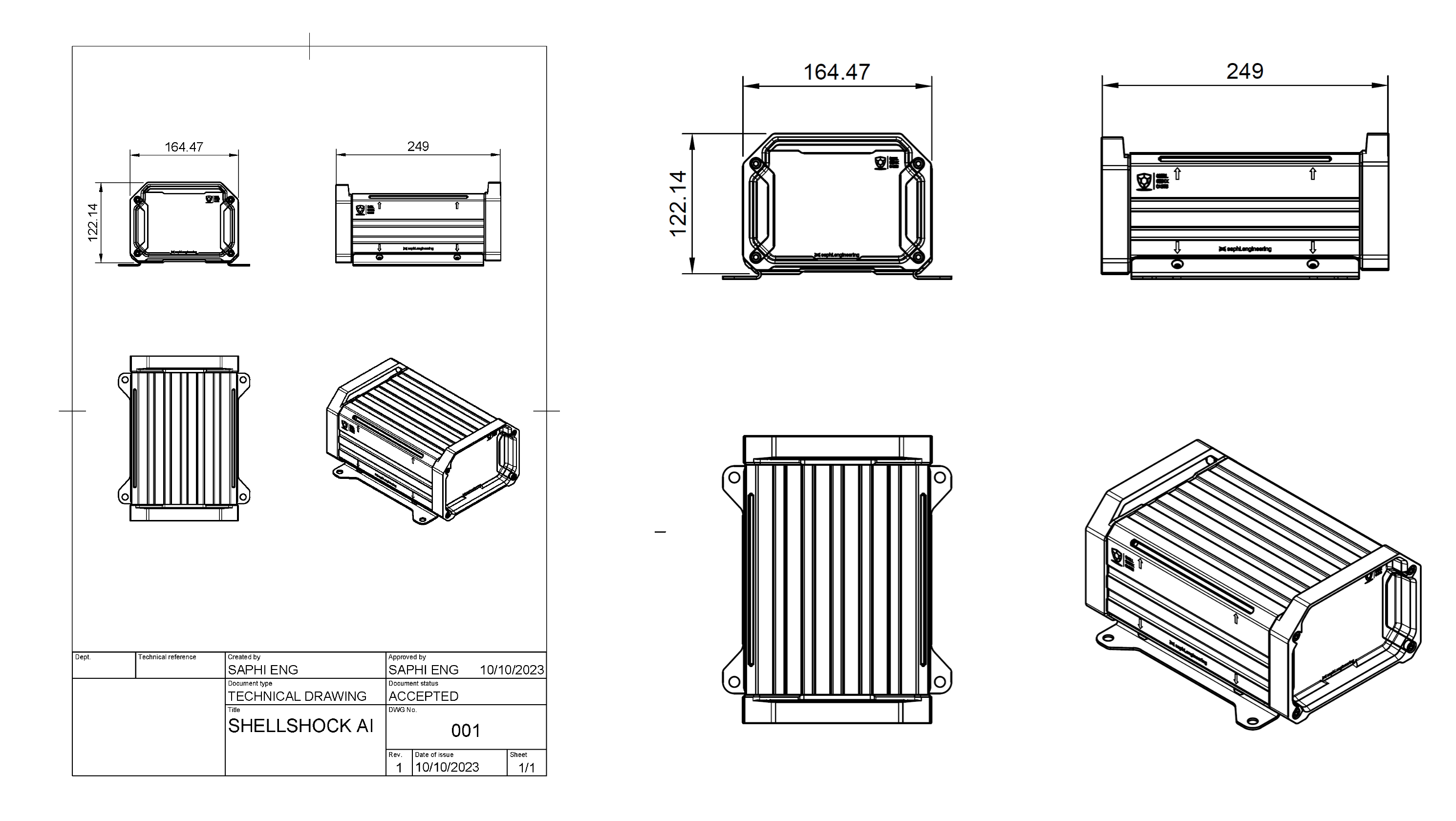

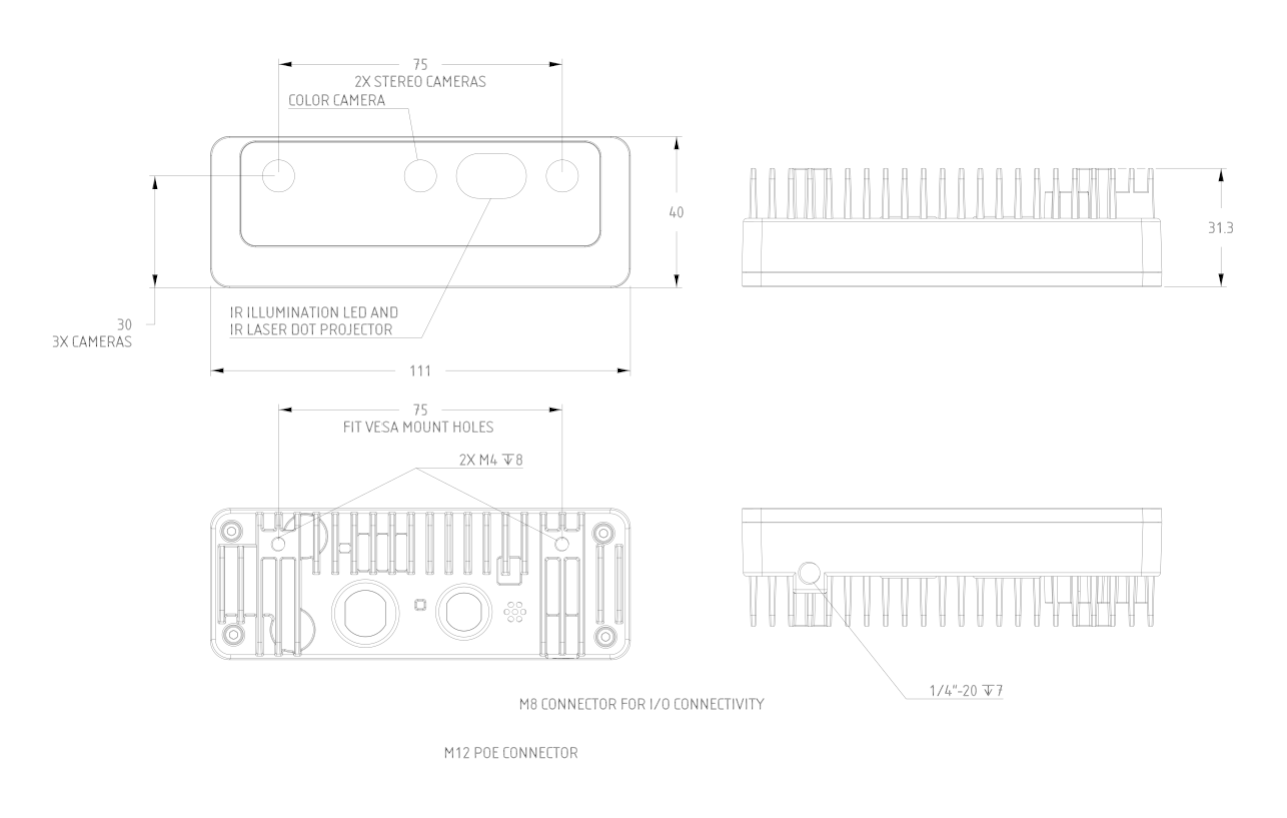

Hardware Size Spec

The below diagrams provide overviews of the size of the housing and camera unit.